Why Quality Metal Manufacturing Depends on Foundry Services

Foundry services play a pivotal role in the realm of metal manufacturing. They facilitate the transformation of raw materials into superior components through accurate casting and molding techniques. Skilled professionals are essential in this operation, as they strive to reduce defects and maintain rigorous testing. Recognizing how these services contribute to overall product quality reveals their more extensive implications in operational efficiency and market competitiveness. What lies beyond this initial framework?

Understanding the Fundamental Role of Foundry Services in Metal Manufacturing

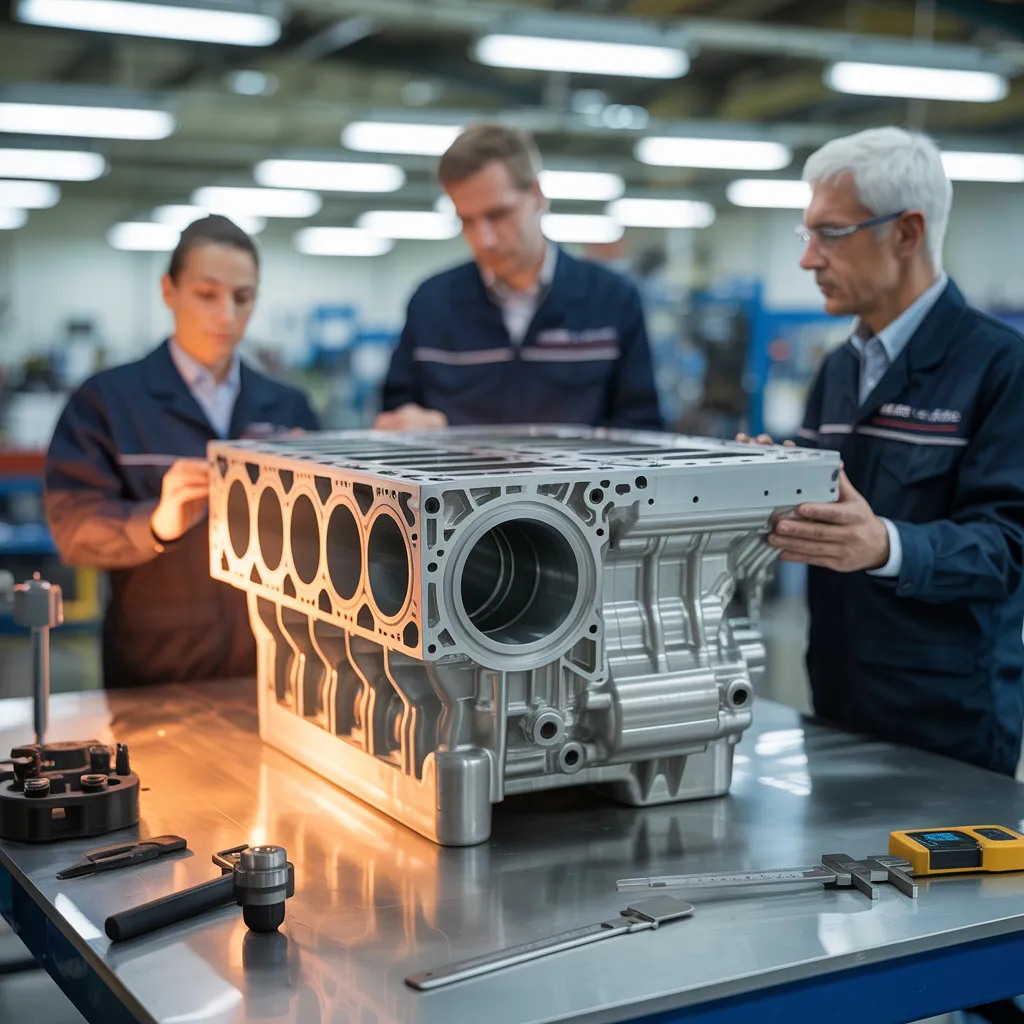

Even though many tend to ignore the relevance of foundry services, they play a vital role in the metal manufacturing industry. Foundry services encompass various processes, including casting, molding, and finishing, which are crucial for producing high-quality metal components. These services support the transformation of raw materials into usable forms, enabling manufacturers to create intricate shapes and designs that fulfill specific industry standards.

Additionally, foundry services enable the production of a wide range of metals, such as aluminum, steel, and bronze, with each needing specialized techniques and expertise. The precision obtained through these services not only enhances the performance of final products but also supports the overall efficiency of manufacturing operations. By understanding the fundamental role of foundry services, stakeholders in the metal manufacturing sector can comprehend how these processes underpin the creation of trustworthy, durable components, ultimately influencing the success of numerous applications in different industries.

Key Advantages of Foundry Services for Ensuring Quality Control

Foundry services substantially boost quality control in metal manufacturing, as they utilize meticulous techniques and rigorous standards throughout the production process. A primary advantage is the expertise of skilled professionals who monitor every stage, guaranteeing adherence to specifications and reducing defects. Furthermore, foundry services implement comprehensive testing methods, including dimensional checks and material analysis, which confirm the quality of the produced components.

Another significant advantage is the use of modern materials and procedures adapted to specific applications, resulting in superior durability and performance of the final products. Consistency is also achieved through established protocols that decrease variability, ensuring uniformity in production.

Furthermore, foundry services support streamlined feedback loops, facilitating prompt identification and remediation of issues, consequently enhancing overall product quality. Ultimately, these factors contribute to a greater level of customer satisfaction and trust, making foundry services indispensable for securing and sustaining quality control in metal processing.

How Does Technology Enhance Foundry Services Benefits?

Technology significantly enhances foundry services by introducing advanced casting techniques that increase precision and efficiency. In addition, real-time quality monitoring systems enable immediate feedback and adjustments, making certain that manufacturing standards are consistently met. These technological advancements not only optimize processes but also improve the overall quality of metal products.

Professional-Grade Casting Methods

As markets advance, advanced casting techniques emerge as a critical component in enhancing the benefits of foundry services. These processes, including investment casting, lost foam casting, and 3D printing, utilize advanced technology to increase precision and reduce waste. By implementing cutting-edge materials and automated processes, manufacturers can accomplish complex geometries that were previously unfeasible. This not only elevates the quality of the final products but also reduces lead times, facilitating quicker market responsiveness. Additionally, these techniques support customization, empowering clients to secure bespoke solutions that fulfill specific requirements. Overall, the adoption of sophisticated casting methods greatly optimizes production efficiency and quality assurance, creating a competitive edge for foundry services in the metal manufacturing landscape.

Real-Time Quality Monitoring

In contemporary metal fabrication, the integration of real-time quality monitoring systems significantly improves the effectiveness of foundry services. These systems leverage advanced sensors and data analytics to continuously assess production processes, making certain that specifications are met at every stage. By providing immediate feedback, manufacturers can rapidly identify and address defects, decreasing waste and boosting overall efficiency. This proactive approach reduces downtime and enhances product quality, ultimately leading to higher customer satisfaction. Moreover, real-time monitoring allows manufacturers to maintain compliance with industry standards and regulations. As a result, the adoption of these technologies not only optimizes the foundry's operational capabilities but also reinforces its competitive edge in the market.

Boosting Product Durability and Performance With Foundry Services

As numerous sectors pursue cutting-edge approaches to improve product longevity and functionality, foundry services emerge as an essential component in achieving these objectives. By leveraging advanced casting techniques and materials, foundries can create components with outstanding strength and resilience. The use of top-grade alloys and precision casting processes ensures that the final products can withstand harsh conditions and stresses, considerably extending their lifespan.

In addition, foundry services include strict quality control measures throughout the manufacturing process, verifying that each component meets stringent performance specifications. This meticulous approach not only improves the durability of the products but also improves their functionality in diverse applications. Moreover, custom foundry solutions allow for tailored designs that satisfy specific industry requirements, further improving overall performance. In this way, foundry services play a pivotal role in enhancing the durability and effectiveness of metal products across diverse sectors, from automotive to aerospace.

Why Professional Foundry Services Make Good Financial Sense

Committing to professional foundry services can deliver significant financial gains for businesses striving to strengthen their manufacturing capabilities. By harnessing expert knowledge and advanced technical solutions, companies can cut production costs through better efficiency and minimized waste. Professional foundries typically provide specialized solutions that optimize the design and manufacturing process, creating higher-quality products that fulfill strict industry standards.

In addition, outsourcing foundry services enables businesses to dedicate attention to core competencies, liberating resources for innovation and growth. This strategic investment can also lead to faster turnaround times, permitting companies to respond promptly to market demands. Moreover, the expertise of professional foundries can decrease the risk of costly errors, which often arise from inexperienced handling of complex metal formulations. Eventually, the financial implications of investing in professional foundry services go beyond immediate cost savings, fostering long-term sustainability and competitive advantage in the manufacturing landscape.

Real-Life Success Stories of Foundry Services in Metal Production

Success stories are plentiful in the field of metal manufacturing, showcasing how companies have transformed their operations through the use of professional foundry services. One noteworthy example is a leading automotive manufacturer that experienced production delays due to inconsistent metal quality. By working with a specialized foundry, they optimized their supply chain efficiency and remarkably reduced defects, resulting in a 30% increase in production output.

In a similar fashion, a machinery firm dealing with high costs and material waste shifted to a foundry recognized for its precision casting competencies. This cooperative effort not only decreased material expenses but also enhanced product durability, generating a 25% increase in customer satisfaction ratings.

These cases demonstrate that investing in professional foundry services can generate considerable operational enhancements, cost savings, and improved product quality. Those success stories emphasize the critical role that foundry services play in the competitive landscape of metal manufacturing.

FAQ

What Types of Metals Are Typically Used in Foundry Services?

Foundry processes generally use diverse metals, including steel, bronze, aluminum, and cast iron. These materials are opted for for their particular properties, which provide the performance, durability, and strength of the final cast products.

How Should I Pick the Right Foundry Service Provider?

To select the right foundry service provider, one should examine their track record, technology, quality certifications, and customer reviews. Comparing pricing and lead times can also ensure alignment with specific project requirements and expectations.

What Are the Main Challenges Found in Foundry Services?

Common challenges in foundry services include unstable material quality, equipment maintenance issues, labor shortages, volatile raw material costs, and regulatory compliance. These factors can substantially impact manufacturing efficiency and the overall quality of metal castings.

How Long is the Foundry Process Expected to Take?

Foundry operations typically require anywhere from weeks to months, determined by the high volume aluminum foundry intricacy of the design, material type, and manufacturing quantity. Variables including mold creation and surface finishing operations can significantly impact the complete schedule.

Are Foundry Services Environmentally Friendly?

Foundry services can be sustainable when utilizing sustainable practices, such as material recycling and using energy-efficient technologies. However, the overall impact depends on specific processes and adherence to environmental regulations within the industry.